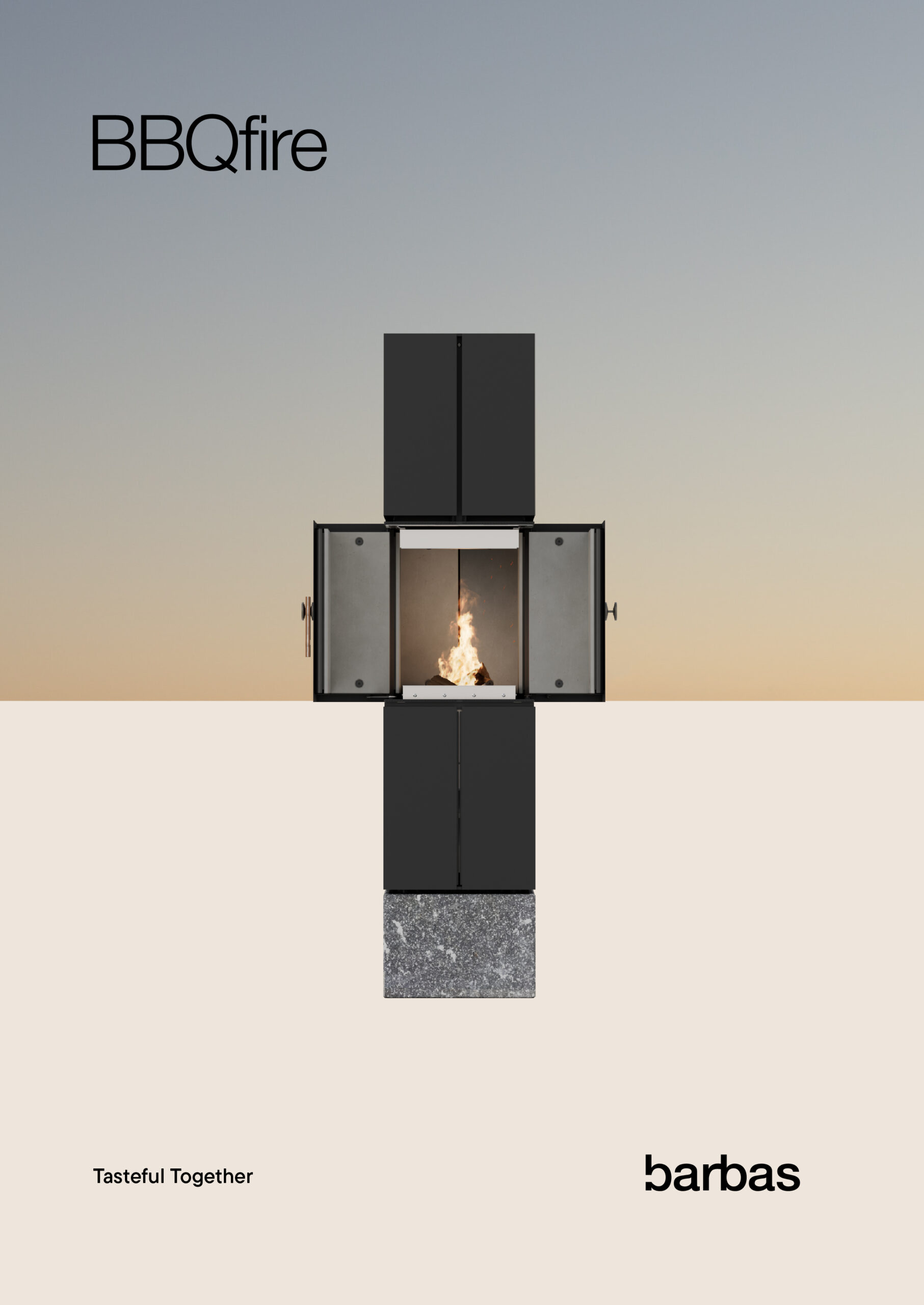

Outdoor – Barbas BBQfire

De BBQfire is een nieuwe ontwikkeling van Barbas Bellfires, speciaal voor buiten. De BBQfire volgt het ritme van jouw avond. Het is een garden piece die moeiteloos transformeert van een elegante BBQ naar een prachtig haardvuur voor onvergetelijke momenten.

Barbas Bellfires

Laat je verwonderen door onze haarden. Staar in de vlammen en zweef naar andere gedachten. Geniet van de optimale vuurbeleving gas- en houthaarden. Met veel gevoel voor stijl, vakmanschap en oog voor detail in onze eigen werkplaats gemaakt.

Wij hebben meer dan 45 jaar ervaring in het ontwerpen en produceren van gas- en houthaarden.

Barbas Bellfires als eerste bedrijf CO-vrij certificaat

Barbas Bellfires mocht op vrijdag 28 november het CO-Vrij certificaat in ontvangst nemen van Jeroen De Vrught van Kiwa. Daarmee is Barbas Bellfires als één van de eerste bedrijven klaar voor de regeling welke per 1 april 2023 definitief van kracht wordt.

Download onze brochures

Ben je op zoek naar een houthaard of een gashaard? Bekijk hier de brochures van Barbas houthaarden en Bellfires gashaarden.

Stijlvolle haarden & kachels voor sfeer en comfort

Waar vroeger de primaire functie van een haard het verwarmen van een huis was, draait het tegenwoordig steeds meer om gezelligheid en sfeer. De dansende vlammen en de warmte van het vuur geven een nostalgisch en magisch gevoel. Barbas Bellfires is dé fabrikant voor haarden en kachels. Wij ontwerpen en produceren al sinds 1976 haarden in onze eigen werkplaats.

Creëer sfeer én stijl met een haard in huis

Droom jij weg bij het idee van een glaasje wijn met op de achtergrond de dansende vlammen van een haard in je ooghoek? Een haard komt in bijna alle huizen goed tot zijn recht, dus ook in die van jou. En de mogelijkheden zijn eindeloos: van inbouw houthaarden tot vrijstaande gashaarden en van 3-zijdige gashaarden tot een tunnelhaard. Onze producten zijn altijd gecreëerd met oog voor detail. Met ons brede assortiment is er altijd een haard die bij jouw stijl en interieur past.

Ook kachels behoren tot de mogelijkheid

Is extra warmte in je huis je voornaamste doel? Dan is een kachel misschien meer wat je zoekt. Lekker opwarmen bij het knisperende hout van de houtkachel of is het gemak van een gaskachel meer je ding? Naast de keuze tussen hout en gas wil het oog natuurlijk ook wat. Hier spelen we op in met stijlvolle kachels: ga jij voor stoer en eigentijds of hou je het liever simpel?